Contents

Whether you need to renew old floors or seal your concrete surface, epoxy flooring can transform your space while strengthening your flooring. This floor covering is surprisingly useful for protecting concrete surfaces and protecting them from hard knocks.

Flooring an auto shop, room or garage has many benefits. Epoxy flooring is durable and seals the floor, bringing safety and beauty to any high-traffic area. If your floor is uncoated and left open to damage, epoxy can protect the floor from further damage and bring a level of professional treatment that may be lacking.

Epoxy floor coating is made from epoxy resin, polyamine hardener and other additives. When not used as a floor covering, it is often used as an adhesive. As it is mixed, it creates a chemical reaction that gives the floor different properties. One of the most important properties produced by this chemical reaction is the stability and durability on the surface. This process seals and hardens the applied surface, creating a strong bond. Check out the advantages of epoxy floor coatings to determine if this is the right choice for your space.

Advantages of Epoxy Floor Coating Systems

Floors are often an important part of workday productivity and safety that we don’t pay much attention to unless they’re an issue. You may want to consider an alternative flooring option for your facility and its potential impact. One of these options is epoxy floor coating.

Epoxy is a material that acts as a sealant for concrete floors. Epoxy floor coatings can be used for commercial buildings on floors, walkways, sometimes even walls or ceilings, and most commonly garage floors. Many facilities that have experienced the benefits of epoxy flooring before are commercial or industrial buildings such as manufacturing plants, warehouses, pharmaceutical buildings, food or beverage facilities, or even laboratories. Here are the main benefits of installing an epoxy coating on your building:

- Durability: Epoxy coated concrete floors last longer and are significantly resistant to abrasion. So you save money and allow you to manage other business problems.

- Strength: Once the epoxy is converted into a solid polymer, it becomes incredibly strong and prevents chemical degradation.

- Saves Time: Epoxy flooring is generally quick and easy to install, which takes less production downtime for installation.

- Ease of Maintenance: Once concrete has an epoxy coating, it is no longer porous since it is sealed and therefore easier to clean.

- Aesthetic Appearance: Veneers are often available in a range of colors and patterns to suit your own style.

- Chemically Resistant: Epoxy coatings can withstand continued exposure to strong chemicals, perfect for warehouses or plants that may be exposed to such materials.

- Security: These coatings are resistant to slip, temperature, extreme impact and even fire, protecting the safety of both your employees and your building.

- Brightness: Typically, a high gloss option can be provided for coatings, significantly increasing the illumination in your facility due to reflection.

- Vehicle care: Choosing an epoxy coating can also reduce wear on vehicles in your facilities because it is more forgiving on machinery.

- Eco-Friendly: Finally, epoxy coatings are a green option for your business due to the reduction in material usage. It is the perfect alternative to adding to a completely new floor or replacing a vehicle due to damage.

Epoxy Floor Coating Types

Bisphenol A

The most popular form of epoxy resin used for epoxy floor coatings is Bisphenol A. Bisphenol A has a honey-liquid consistency and is an extremely versatile resin. Bisphenol A is available in many molecular weights. The variety of molecular weights makes Bisphenol A particularly versatile for epoxy application. Bisphenol A is most commonly used for flooring systems in addition to solid coatings. Bisphenol A contains important physical properties and is highly chemically resistant.

Bisphenol F

The properties found in Bisphenol F tend to be less sticky than those found in Bisphenol A. Bisphenol F epoxy resin will typically be more expensive than Bisphenol A epoxy. This is because Bisphenol F epoxy can be used for a wider variety of applications. Bisphenol F is particularly chemically stable. As varnishes they are more likely to be used in applications related to water pipes, adhesives, supermarket food packaging, plastics, dental fillings and linings.

Metallic Epoxy Floor Coating

Metallic epoxy flooring is durable and has a visual impact that cannot be created using regular paint. Metallic epoxy floor coating pigments can create a sense of movement and depth on a floor. This coating is very popular for commercial and high-traffic retail applications and leaves a striking effect on the surface of any floor.

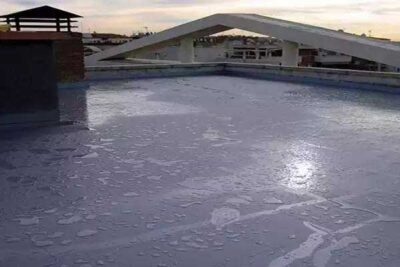

Transparent Epoxy Floor Coating

Clear epoxy floor coating is typically used to cover concrete floors because of the advantages the materials it contains. It can be used on top of an originally painted surface to coat the paint structure with a more durable and long-lasting consistency. Transparent epoxy floor coating is mainly used for the application of garage and parking lot flooring.