Polyurethane waterproofing consists of two components, the base and the reactor. Polyol acts as the base while isocyanide is the reactor component. Combining both in a given design ratio creates a liquid coating for waterproofing applications. Polyurethane is a very popular choice due to its ease of assembly. Unlike other waterproofing systems such as sheet membranes and liquid applied membranes, this polyurethane application requires relatively little skill and supervision. The application is fast and such processes can also be used for post-construction applications.

Detailed methods for surface preparation and application are determined by the product supplier and are often overseen by the product supplier in large project applications. Waterproofing is a costly process, however, it is better to prevent leaks and take all precautions during the construction phase.

Advantages of Polyurethane Waterproofing Systems

- Easy and fast installation

- Perfect result

- Long-term durability and high resistance to wear

- UV and weather resistant

- Resistant to alkaline cleaners, battery acid and fuels

- Optimal level of flexibility

- Sufficient thickness of the application layer is only 2 mm

- After hardening, the weight of the material is minimal, so it can be used in lightweight constructions.

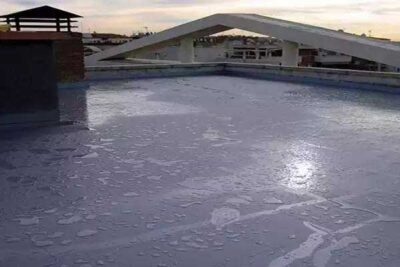

Polyurethane Waterproofing Procedure

- The ceiling surface is completely cleaned and free of foreign matter.

- Cracks in the surface preparation bed are cut into the V part, cleaned and filled with 1 part polyurethane based crack filler and 2 parts white cement. (12)

- The surface should be neutralized by removing alkalinity by means of acid application.

- To be used as an adhesion coat, two packs of polyurethane primer coat is first applied to the surface. It is left to dry for at least 8 hours.

- Three consecutive topcoats are then applied, each brushed with 2-component polyurethane mixed to the design ratio. Each layer is allowed to dry for at least 12 hours before applying the next.

- Polyurethane waterproofing coating continues 150 mm to parapets or walls. In addition, rainwater pipes should be continued at least 100 mm.

- The final Polyurethane coating is sprinkled with a layer of 300 micron grit.