Contents

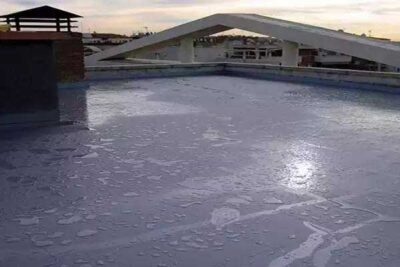

Epoxy mortar floor trowel system is a solid color, resin-rich, aggregate-filled, seamless, epoxy-based floor repolisher with high density and compressive strength for exceptional durability. Typically installed to protect new concrete or re-profiled existing worn floors 3 – 6 mm thick. This heavy-duty general-service epoxy system exhibits good chemical resistance as well as superior abrasion and impact resistance.

The epoxy mortar trowel system can be customized to meet aesthetic and slip resistance requirements. The final surface appearance for the epoxy mortar system includes unlimited choice of colors, light or heavy orange peel, integrated cove base and variable surface texture to produce a variety of rough slip resistant or smooth surfaces.

Why Choose Epoxy Mortar Floor System?

When choosing the best flooring for an area within a commercial or industrial facility, the conditions to which the area will be exposed should be considered. Many industrial facilities have areas that will be exposed to regular conditions, such as storing and moving heavy loads and traffic from forklifts and other heavy vehicles. Flooring in such areas will require more protection to continue to perform well over time.

Epoxy mortar systems are often a viable flooring option for areas that require this extra level of protection. Epoxy mortar floor coverings can carry heavy loads, protect against pitting of concrete flooring and have excellent wear resistance to withstand the action of heavy machinery. They can also help against slips and falls by adding additional tissue to improve worker safety. Epoxy mortar is mainly installed for areas that need to withstand heavier daily wear and tear.

What are the Benefits and Advantages of Epoxy Mortar Flooring System?

- Extreme Endurance

It is flexible enough to provide comfort in areas where personnel are walking or standing for long periods, yet tough enough to withstand high foot traffic, vehicular traffic, wheeled loads and possible ground impact. - Wear resistance

This property will have the ability to resist the abrasion of floors, which typically occurs when a hard rough surface slides along a softer surface, which then causes undesirable removal of material from the surface. - Chemical Resistance

The chemical resistance feature provides protection for all areas where chemicals and liquids can penetrate the flooring. Chemical resistance regulates a material’s immunity to corrosive environments. - Increased Light Reflectance

Epoxy floor reflects light from the ground, increasing brightness by up to 300%, increasing visibility within the facility; It allows you to save electricity usage. - Anti-Slippery

An optional coating that you can add to your floor coverings is non-slip flooring. This plugin will let you worry less about possible accidents happening. In some areas of industrial plants this is a very important factor. - Smooth and Seamless

One installation option available is a smooth seamless system where the flooring will look seamless from all sides with a gorgeous smooth glossy finish. This seamless flooring option is also antibacterial. - Easy to Clean and Maintain

The materials used to install these flooring systems and the flawless application of the floor make for super easy maintenance and easy cleaning of floors.