Contents

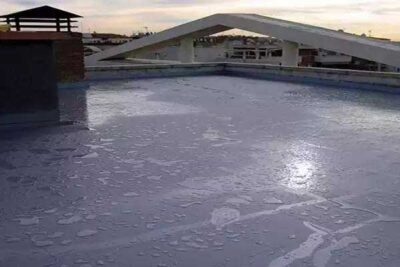

Cost-effective, flexible, versatile, reliable, positive waterproofing against harmful moisture migration and free water infiltration in foundations, basements, roofs, retaining walls, etc., using membrane types and membrane coating types such as PVC, APP, EPDM, TPO, SBS Bitumen. provides. It also offers a fast and easy-to-implement system for maximum productivity.

What are the Advantages of Membrane Coating

- Specially designed membrane assortment helps to meet and maintain the maximum flooring moisture required by the flooring industry’s specifications and offered in the low temperature version. This superior range of membrane coatings exceeds the waterproofing capabilities of other sheet membranes or liquid coatings for all other business features such as floor tiles, underfloor roofs, windows and roofs.

- It is ideal for even inverted roof type as a damp proof under membrane coatings, flat cement concrete, foundation, bridges, basement and underground works. Waterproofing under tiled roofs of swimming pools, tanks, reservoirs, agricultural fields, gardens and greenhouses etc. It is unmatched for waterproofing.

- Membrane coating is a plastic-reinforced bituminous waterproofing layer consisting of multi-layer plastic, modified bitumen and polyester / fiber glass blanket. The membranes have a central core of high molecular high density polyethylene that is waterproof on its own. Since the product is a plastic base, the efficiency of the system does not wear out over time. Plastic does not degenerate or deteriorate and the system is expected to operate for at least 20 years.

- Membrane varieties have extreme temperature resistance and very good elongation to absorb all structural movements. With its high tensile strength, the membrane is extremely flexible and suitable for conforming to contours.

What are the Membrane Types

1. APP Membrane Coating

APP Membrane varieties use polyester reinforcement or fiberglass reinforcement as original source, APP, APAO as modifier, and cover waterproofing materials as polyethylene, sand or gravel. APP (Atactic Polypropylene Plastomeric) type consists of a specially formulated bituminous composition of distilled asphalt modified with selected high grade visco-elastic polymers and reinforced with 300 g of high quality non-woven polyester carrier. The APP membrane is covered with a sanded top surface coating, while the bottom surface is protected by an embossed and heat sensitive polyethylene film. This type of coating for the substrate was chosen for two specific purposes.

APP modified bitumen is a plastic bitumen mixture modified using plastic in the form of atactic polypropylene (APP). When installers begin torch application of APP, such plastic begins to melt at a point of 148°C, where it melts into a liquid wax-like substance that behaves almost like a free-flowing liquid that can then be wiped across a surface. The APP has a high temperature tolerance during heating, so it is more user-friendly for installers. This ease of melting makes APP bitumen popular on smaller roofs such as residential properties and commercial flat roofs.

2. EPDM Membrane Coating

EPDM Membrane is a lightweight, durable and weatherproof single-ply waterproofing membrane perfect for a wide variety of applications. It has been proven for over 20 years that it can withstand extreme temperature fluctuations and constant exposure to direct sunlight. It also has exceptional flexibility and will not split or crack under normal building action. EPDM waterproofing membrane is an effective and high-performance waterproofing system with 100% waterproofing duty for contemporary buildings.

EPDM is elastic and tear resistant at low temperature. EPDM roof sheets can be machined on pipes and slopes in all weather conditions and fit neatly around such projections. In addition, EPDM membrane types do not need sun protection as they are resistant to UV rays and normal measures can be taken to reduce heat transfer through the roof structure, ie insulation.

Typical installation methods of EPDM include loosely laid ballast, mechanically fixed and fully bonded systems. Because there is no heat or open flame associated with installing EPDM roof systems, they are generally considered easier and safer to install. The seams along the edges of the EPDM sheets are typically adhered using a manufacturer-supplied seam tape or a liquid adhesive.

3. TPO Membrane Coating

TPO membrane, a new type of waterproof material produced using polymer production technology, combines both polypropylene (plastic) and ethylene-propylene (rubber). Plasticizer-free TPO membrane variants provide long-term flexibility. The result is an ideal commercial waterproofing membrane that is reliable, cost effective, environmentally friendly and easy to install.

TPO Membrane (thermoplastic polyolefin) is a single-ply reflective roofing membrane. It consists of polypropylene and ethylene-propylene rubber that polymerizes together to form what we call TPO. This synthetic membrane coating comes in a variety of thicknesses and sizes. Typically, customers can find it in the market in thicknesses of 45 to 80 mils. TPO is usually only available in three colors, white, gray and tan. If you want to get an energy-efficient cool roof, you can choose the white color that reflects the solar energy effectively. This also reduces the impact of the building’s energy consumption.

4. Firestone Ultraply TPO Membrane Coating

Firestone Ultraply TPO Membrane is a flexible, environmentally friendly, fast to install and safe to use, high performance Thermoplastic PolyOlen roofing membrane made from the incorporation of an ethylene propylene rubber into a polypropylene matrix and reinforced with a polyester weft attached reinforcement.

Committed to providing outstanding quality and optimum environmentally friendly waterproofing solutions. Benefits; It ranges from heat reflection and energy efficiency to environmentally friendly roof systems.

Suitable for a variety of low slope roofing applications, Firestone UltraPly TPO Membrane is a sustainable roofing solution for a wide variety of building types. Firestone UltraPly TPO membrane also offers design options with reflective white, tan or gray panels that can help reduce a building’s cooling requirements. White and tan UltraPly TPO membranes meet National Energy Efficiency Standards for Residential and Non-residential Buildings. These standards define cold roofs to have at least three years of aged reflectance of 0.55 and a minimum thermal emittance of 0.75 for low-slope non-residential buildings.

5. PVC Membrane Coating

PVC Thermoplastic waterproofing membrane is a high polymer waterproof material that is processed by mixing with plasticizers, UV absorbers and other additives using Polyvinyl Chloride Resin (PVC) as the main material. It is a polyester reinforced material that provides the high tensile and tear strength required to prevent excessive elongation and sheet deformation under the stresses produced by lifting the membrane under load by wind.

PVC Membrane is a single-ply roofing membrane covering used on commercial or industrial roofs. Similar to other membrane roof coatings such as TPO and EPDM, PVC can be applied over existing roofing materials for an environmentally friendly roof restoration. It is an excellent choice for creating a durable, waterproof coating for flat and low-pitched roofs.

PVC membrane assortment is a cost-effective alternative to traditional roofing systems and can be produced in a multitude of colors to coordinate individual building project needs. Manufactured in bright white, this flexible fabric membrane reduces radiant heat gain and keeps interior temperatures cooler in hotter weather.

6. SBS Bituminous Membrane Coating

SBS Bituminous Membrane range is a high performance rubber modified bitumen membrane reinforced with a combined reinforcement (polyester and fiberglass). The exceptional elongation properties of SBS bitumen membrane combined with the strength and dimensional stability of the reinforcement provide an excellent waterproofing membrane for new and existing structures. The SBS is sanded or coated with a top surface coating, while the lower surface is protected by an embossed and heat sensitive polyethylene film.

SBS-Modified bitumen membrane consists of synthetic rubber modified bitumen by adding styrene-butadiene-styrene (SBS). It doesn’t melt in the same way as this APP, instead it offers ‘sticky’ melting that gets hotter. This lack of fluid flow takes less heat and provides a faster setup compared to APP. SBS systems can also be mounted with cold glue to projects where open flames are not allowed.

Due to the rubber used in its structure, SBS bitumen is more flexible than the plastic used in APP. This flexibility means it has recovery properties that allow it to withstand the stresses created by wind, temperature fluctuation, and expansion and contraction. Besides faster installation times, SBS bitumen is not affected by oxidation or aging.