Contents

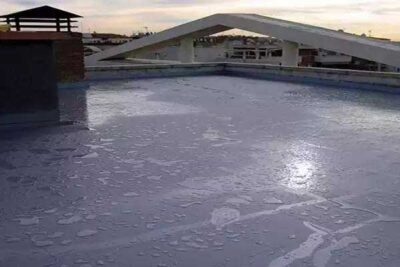

Pool insulation is a critical component of the civil work required when building a pool. Waterproofing the facility is accomplished quickly by applying a solid waterproof cement mortar to the walls and bottom of the pool, acting as a pool insulation and smoothing layer at a consistent time. Thus, the smooth, solid and waterproof surface required for the application of tile mortars is created.

For a swimming pool to last for many years and not require constant repairs, it is essential that its structure be waterproofed in a timely manner. Pool insulation plays a very important role in sealing the pool and ensuring its longevity. This is because water puts serious loads on the swimming pool structure and is a factor in both its frame and all the materials used in its construction.

Pool Leaking Water; Over time, the constant pressure of the pool water can be combined with fluctuations in the ground pressures surrounding the pool, causing water leaks and cracks. Swimming pools are exposed to enormous internal and external forces. When a crack appears, it tends to expand and serious leaks can occur. It’s time to waterproof your swimming pool. Fortunately, Dekorizon has cost-effective solutions for the problems.

The advantages of compounds that provide waterproofing of the swimming pool are:

- High degree of impermeability against water, which ensures full impermeability of water and prevents water leakage,

- The ability to increase the strength qualities of surfaces,

- Good adhesion with the base material,

- Good frost resistance and penetration degree of the mixture,

- Protection of the pool structure against corrosion and aggressive chemicals,

- Useful and simple application,

- Preventing the spread of microorganisms and molds,

- Environmental and sanitary robustness.

The general material used in the construction of the swimming pool is reinforced concrete with the benefit of positive or negative waterproofing. While designing a suitable waterproofing system for pool insulation, attention should be paid to both water inlet and water outlet. A waterproofing master must consider many factors, such as grades and dimensions of the concrete structure. Is soil retained at all heights, what are the finished surfaces intended to be applied over waterproofing, and is it directly exposed to UV rays?

The degree of insulation required for a pool insulation varies depending on where it sits in the building. A swimming pool where diving is not an issue, over a parking lot or parking lot, will only require a low or medium level of insulation system. Pools on the upper floors of buildings require a high to very high level of pool isolation using spring-loaded connections and must include access to assemblies for leveling and inspection. The air gap has the advantage of increasing the insulation performance.

Pool isolation systems are individually designed and must be verified by a specialist acoustic performance to verify fitness for purpose. Another major concern, especially with thinner concrete rises or sections; is the flexing of the pool liner when both filled and emptied. Maintenance, cleaning, replacement of defective tiles, etc. Frequent filling and emptying may be required. These flexing / tensile bending events can cause post-application fluid failure or formation of waterproofing types. This is always the best advice for emptying and refilling pools. One way to significantly reduce this particular risk is to identify a type of fully bonded, elastomeric waterproofing that will be applied directly to its surfaces, while having the necessary resistance to both water and any other substance, yet capable of resisting cracking.

Using a more rigid process type system will inherently increase the risk as they are more likely to break from a structure on the flex and therefore lead to waterproofing failures.

Elements to be Considered While Performing Pool Waterproofing

An important aspect to consider when insulating pools is that the surfaces involved are usually in contact with two types of water; groundwater and the water inside the pool. Due to the aggressive nature of groundwater, it is necessary to carefully consider its level and whether its presence is constant or temporary. As for the water inside the pool, it contains chlorine and other substances that can destabilize the structure. For these reasons, the walls of the pools should be carefully waterproofed and protected.

Many problems can be avoided at the planning stage of the construction or renovation of pools. Waterproofing alone is not enough. It is very important to protect surfaces and walls from all aggressive substances that can compromise their durability. Other key factors to consider are;

- Sealing stage of castings and plant engineering system,

- Circulation systems,

- Water filtration and lighting

In fact, all of the above-mentioned elements represent critical considerations for proper waterproofing. At this point, it is clear that we need special products with different properties to effectively waterproof pools.

Pool Insulation and Crack Repair

The walls and floor of a swimming pool are subject to various leaks such as inlets, scraper throats, lighting fixtures, cleaning systems and more. All this and the constant water pressure can cause leaks. Concrete shells must be sealed to ensure they retain water. For this reason, it is necessary to implement a system of pool isolation to keep the water in the pools of hotels, clubs or large societies and to ensure that everyone can enjoy swimming uninterruptedly.

There are a number of high performance pool isolation solutions available. The important thing is to use a suitable application for pools and chemically treated waters. A suitable sealant is reliable and guarantees watertightness. In addition, it is super flexible, compatible with a variety of designs and provides the perfect finish for any swimming pool.

Steps for pool insulation:

- To begin with, contaminants such as oil, dust and debris are removed from the substrate by pressure washing, sandblasting and grinding.

- All leaks, joints, seams, corners, strainers and expansion/control joints are then sealed that could weaken the best pool insulation system. The surface is then cleaned with a wet sponge and allowed to dry before the membrane is applied.

- When the pool insulation is ready, the entire surface is covered with a membrane according to the manufacturer’s specifications. In order to facilitate a strong bond for the waterproofing membrane, it is very important to control the restrictions in the temperature ranges during application. A quality product is typically plastered in three layers.

- After one week of curing, a leak test is performed to ensure the pool is waterproof to begin the tile or terrazzo installation. However, if any water leaks are detected, there is apparently a glitch that needs to be fixed with repairs.

When it comes to pool insulation, it is important that the job is handled by a professional team to ensure effectiveness. Dekorizon is a company specializing in pool insulation with methods that provide the highest level, reliable and long-term protection of swimming pools.

Sealed Concrete Pools

Sealed Concrete Pools

One of the most important steps in gunite or concrete swimming pool construction is choosing the right type of waterproofing. Concrete is a porous substrate prone to water seepage; therefore, the water in the pool needs to be sealed, as well as keeping out the forgotten groundwater.

Every swimming pool or water feature should be waterproofed if there is a pool water leak in some way. Sometimes these structures present challenges and become difficult to waterproof due to the various leaks involved in the design to accommodate elements such as lighting, piping and drainage.

There are various products for pool insulation on the market today. Before any final decision is made, the following information will help facilitate material selection and increase success rates.

Cement-based coating and waterproof barrier products tend to bond better with the concrete composition. Because they are similar in chemical composition and are enhanced by polymer binders. These products also allow for a variety of finishing options; Plaster, coatings and adhesives adhere better to cementitious surfaces as opposed to pure polymer waterproof coating.

When dealing with new pool construction, cementitious linings are not susceptible to failure from moisture vapor transmission, the rate at which water vapor passes through a material at a given temperature and relative humidity. These coatings are breathable, so they can be applied only a few days after the concrete is poured or the gunite is placed. In contrast, pure polymer systems require the concrete to cure for at least 28 days to prevent degradation of moisture vapor transmission.

In swimming pool repairs, it is often difficult to completely dry the substrate before waterproofing is applied. Pure polymer coating systems cannot be applied to surfaces that are not completely dry, cementitious products are moisture tolerant. In fact, many manufacturers even require pre-wetting the substrate prior to application.

Ease of Application

When choosing a waterproof coating, keep the project handy. For example, vinyl-lined pools can be more difficult to work with if they have a non-standard shape. However, larger surface areas can be more economically covered using spray equipment as opposed to applying with a trowel or brush.

If a waterproof coating is applied to an uneven substrate (for example, artificial stone flooring in a pond or waterfall feature), applying the coating by brush or roller will make it easier to ensure that all corners and cornices are covered. Additionally, hand-applied coatings do not require expensive sprayers or air compressors.

If the pool owner wants a certain aesthetic appearance, it is important that the waterproof coating or membrane allows for what the pool owner wants. Note that not all coatings are compatible with all adhesives, plasters or other finishes. Since tiles and pool plaster are not waterproof, it is extremely important to use a waterproofing membrane underneath them to extend the service life of the pool.

When a waterproofing product is not used, the potential for water leakage and leakage increases significantly. Leakage can cause water loss, damage the environment (if the pool is suspended) and ruin the plaster / topcoat. Additionally, the rebar/reinforcing steel in the concrete or gunite pool may also be damaged.

Resistance Pressure

One of the most important factors to consider when choosing a waterproof product is its ability to withstand negative side hydrostatic pressure, which is the pressure of water passing through the substrate and pressing against the back side of the coating.

Remember, the coating works to retain the water structure; however, its job is to ensure that groundwater does not obstruct or cause deterioration of the coatings applied to the interior of the pool.

As groundwater or rainwater accumulates, it can pass through the concrete pool shell from the outer surface, causing negative hydrostatic pressure to build up behind the liner. When water gets on the coating, it’s literally trying to push the coating away from the surface. Flexible coatings can swell under this type of pressure and often fail. To counter this, when constructing an in-ground swimming pool it is important to use a base or first floor that can withstand negative hydrostatic pressure.

Water Sanitation Method

Proper water chemistry is important to ensure safe and consistent swimming pool operation. In fact, the sanitation method used in a swimming pool is an important factor to keep in mind when choosing the pool insulation material and topcoat. Where waterproofing is also the finished wear apron (i.e., in direct contact with water and exposure to chemicals, where it is protected, under plaster), it is more important that the coating is resistant to the environment.

Private pools typically have chlorine content of one to three parts per million (ppm), while in commercial or public pools, levels can be as high as 15 ppm to combat bacterial growth. Besides chlorine, ozone and bromine are also used to fight bacteria, and all three can potentially cause pool linings to deteriorate. It may break, discolor and pit due to chemical attack.

Is There a Water Leak, Is Your Pool Leaking?

Is There a Water Leak, Is Your Pool Leaking?

Leaks and leaks in swimming pools often develop gradually and can be difficult to detect. If you have an automatic refill device, you may not notice anything when your water bill increases significantly. If you live in a hot climate, you can attribute the drops in water level simply to evaporation. If you’re unsure, a simple “bucket test” can help you determine if there’s an issue that needs fixing:

- If you have an autofill device, turn it off.

- Fill a bucket with water and mark the water level.

- Mark the water level in the pool.

- Place the bucket on the first or second step of the pool (this will equalize the conditions in the hive and the pool).

- Leave for 24-48 hours.

Theoretically, the water in the pool and bucket will evaporate at the same rate. Therefore, if the level in the pool drops more than the water level in the bucket, there may be a leak. This isn’t exactly an accurate test, but if you notice a significant difference, it’s probably time to call a professional. Other signs of leaks include:

- Cracks in the pool floor indicate settling soil. This causes cracks in pools.

- Puddles outside the pool with no other explanation.

- If you need to use more chemicals in your pool than in the past, it may be because your pool water is changed at a faster rate due to leaks.Havuzdaki Sızıntılar Nasıl Bulunur

Detection of water leaks in swimming pools is a step-by-step elimination process between 4 main areas; Pool Lining, Pool Lights, Pool Plumbing and Pool Equipment.

Leaks in the Pool Covering

- Vinyl pools; It has the most vulnerability in this area, with the potential for minor tearing in vinyl or leaks around deliberate cuts for light, steps, skimmer and drains.

- Concrete pools; It can leak from a crack in the lining, most commonly a very small gap from the wall in the tile line or at the interface of the plastic scoop and the concrete pool wall.

- Fiberglass pools; it can also leak from a crack in the lining, such as a concrete pool, or on bucket, return, drain, or light front surfaces.

- Close all plumbing lines (skimmer, main drain, returns) to find leaks in the pool liner.

- You can use a rubber or threaded plug (the kind used for winterizing). Turn the pump off at the switch so it won’t turn on while the lines are plugged in. You may also need to wait for the pool’s water level to drop because if it continues to drop you may need to drain the pump for a few days. Once the water level has stabilized at the lowest level, increase the water level to normal before starting this test to avoid confusion.

- Often times, if the leak is large enough, it will quickly fall into the problem area and stabilize. This can be right under the skimmer or just below the turns or at the pool light. If the pool water level continues to drop with all lines closed, you can rule out underground plumbing (your biggest fear). However, once you plug in the pipes and turn off the pump, the leak stops.

- If the water level appears to be stable (note that unless you completely cover the pool with a solar blanket, evaporation will continue and you will need to subtract precipitation), you can begin to examine the waterline area closely.

- When you have a leak in your pool liner or vinyl liner, you’ll often see small pieces of debris that have sunk into the crack or ripped the vinyl. Use food coloring or a dye syringe to test the area with dye to confirm a leak in a suspected area.

- The paint test is done with the pump off to reduce currents. Pour a small amount of test paint to see if it moves near the area and gets absorbed through a hole.

Pool Skimmer Leaks

- One of the most common areas in an in-ground pool, leaks can be caused inside the skimmer body or on the sidewalls of the skimmers, often from frost damage or excessive ground movement in winter.

- With vinyl liner pools, the fascia and gasket are always the first suspects and a paint test can be done as described above. Rust on the skimmer front panel or vinyl liner can be a sign of leaks and can cause rust to form on the pool walls, which can damage the liner and walls.

- Vinyl pool wall and flooring fittings all have two seals, one under the liner and one above the liner. It is important to replace both front cover gaskets and if you need to make changes be sure to use only the stainless steel faceplate screws. Other screws may not be properly tightened and may rust.

- For concrete pools, look inside the base, where the pool floor meets the plastic skirting front. Inspect for cracks and debris stuck in the cracks. The paint test will verify leakage, usually on one or more of the three sides, directly where the concrete pool meets the plastic bucket, which changes at varying speeds and shrinks at different rates.

Leaks in the Pool Lamp

- The tube that carries the lamp cable from the light niche to the light junction box is not sealed and can break from changing floors or frost damage.

- If your pool water drops below the water level, below the returns, and is fixed at the top of the pool light, you likely have a leak in the pool light channel behind the pool light.

- Duct leaks are difficult to paint effectively to test, so when a pool light leaks, the usual repair is to seal the opening where the light cable exits the niche and enters the duct.

There are 3 ways to turn off the light channel and you can do it underwater without draining the pool, but if the water level is low, it may be easier:

- With a golf ball-sized piece of mixed pool putty, create a mound around the bead as it enters the channel. Press it against the cable and close it tightly. Cure with the light above the deck for 2 days before replacing the lamp. It can be done underwater with a mask.

- With a 100% silicone tube, squirt into the light channel and the end of the channel to seal the water outlet. Once a good silicone plug is made, let it dry with the light on the deck for 2 days before placing the light in the niche.

- Use a product called Light Cord Stopper. This is a plastic plug that fits around the cord; push it into the channel providing a quick seal. This method is preferable if you need to replace the lamp down the road, as you won’t have to bother removing hard-to-remove sealant or silicone from the tube.

Reasons for fixing pool leaks; Pool leaks not only waste your treated and heated pool water, they can also lead to other problems such as corroded pool walls, erosion of a sandbox floor, pool deck or support soil under your pool equipment.

How to Provide Pool Insulation

If you need to waterproof your swimming pool, there are many effective products on the market:

- Pool liners are UV treated to cover the entire pool, ideal for areas around an above ground pool where ground movement can be an issue.

- Pool paints contain chlorinated rubber and 2 packs of epoxy paint. It is important to choose a paint designed for use in swimming pools and use as directed, or employ a professional line of business for you.

- Resin-based waterproofing products are specially designed to fill cracks in swimming pools. They are carefully injected into the cracks. They remain elastic when cured, so they can expand and contract with more movement in and around the crack. In some cases a harder epoxy resin may be required. The most suitable product for your pool should be determined by a professional pool repair specialist.

- Cement-based coatings are cement-based mortars and paints containing special additives that provide excellent waterproofing. They can be applied with a brush or sprayed. Decorative top coats can be applied for pools.

If you have a tiled pool and choose to repair the leak and leak rather than remodel the entire pool, you will likely need to remove and replace some tiles to get to the source of the leak. Getting professional advice and assistance in waterproofing your pool is best for any solution you use.