Contents

Polyurethane injection, also polyurethane grouting, is a waterproofing technique that uses expanded injected polyurethane to prevent water from flowing through it, typically using voids or cracks in the concrete. This is particularly effective in solving water leak problems when applied below the leak area or on the subfloor ceiling where the leak is occurring.

A hole will need to be drilled in the lower part of the ceiling first to allow the polyurethane foam to be injected using a pressure machine. The pressure causes the polyurethane to rise into cracks or voids from water damage, which fills completely when it expands. Polyurethane injection is a recommended method to be applied to actively leaking cases involving concrete floors.

Polyurethane Injection to Repair Cracks

After the polyurethane injection goes into a water-expansion process, any cracks filled will have a mixture of water and polymer foam type polyurethane mortar. The mixture will then expand until there is no room left to fill and will successfully seal the paths where water enters the material.

Settlements

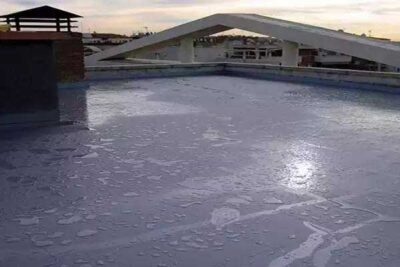

Polyurethane injections are a cost-effective method of repairing leaks into your home, especially outside water. Polyurethane can also be injected into the roof to prevent further leakage and property damage.

Industrial Features

Polyurethane injection is also commonly used to repair factory or warehouse floors that can become damaged after prolonged and repeated use of heavy machinery such as forklifts. Polyurethane joint can also be applied in many areas where there is visible leakage. It is widely used in areas such as drainage, piping and ceilings. Similar to residential applications, you can use it to repair any damage to your properties due to rain or leaks.

Typical Causes of Building Cracks

Poor Drainage

Moisture is the main cause of structure cracks. Poor drainage can cause water leaks that create holes and wear away concrete and other building materials over time. Almost all properties are susceptible to damage from water and moisture. Leaks and cracks they may cause can be successfully treated with polyurethane injection.

Heavy load

Heavy loads from the regular transport of machinery such as forklifts and trucks will cause cracks in the floor over a long period of time. Often in areas with high traffic volumes, cracks can be serious. Because many warehouses with tin roofs can leak over time, water in the ground causes holes and gaps in cracks, which can be repaired by filling with polyurethane.

Wear and Tear

Water remains the most common cause of cracks in buildings. As buildings age, cracks can appear due to wear and tear, especially if there is insufficient maintenance level. This is especially important in areas such as roofs, balconies and wet areas exposed to water. Filling these cracks with polyurethane can help prevent leaks without a major refurbishment.

Polyurethane Properties

Polyurethane is a liquid resin that can be injected into cracks and other voids in concrete structures. When injected into concrete during leak repair, polyurethane undergoes a chemical transformation from a liquid to a solid within minutes.

Polyurethane’s suitability as a waterproofing method is due to its natural properties. It has a very short curing time. This makes it an ideal material for sealing active leaks. It has a low viscosity and allows it to easily seal small cracks after curing on moisture. After an injection, the polyurethane will improve and maintain its flexibility, allowing subsequent movement in the structure while keeping the voids closed, thus preventing leakage from occurring.

Advantages of Polyurethane in Waterproofing

If you are considering using the polyurethane injection method for leak repair, it will be helpful to know that it has some advantages over other waterproofing methods. Polyurethane is a versatile polymer with industrial applications for coating and insulation. It is a strong adhesive and waterproofing material.

Because it is flexible and tough, polyurethane will provide good protection against membrane cracks and building movements that can compromise waterproofing effectiveness. Being highly elastic, it provides resistance to thermal expansion and degradation by exposure to sunlight. This makes it one of the most suitable methods for application to surfaces such as roofs and balconies.

It is popularly used to repair active leaks due to its fast drying properties and ability to seal small sheet line cracks and are otherwise difficult to detect. Compared to other methods involving heavy hacking, it is a relatively clean and low cost solution. In addition, it requires little or almost no maintenance.

Polyurethane Injection Waterproofing and Leak Repair

Cracks in concrete structures can be caused by wider environmental factors such as thermal movement, soil movement due to nearby construction works, and others. While not severe yet, minor cracks do not cause any visible leaks or damage. However, cracks will often increase over time due to water penetration, resulting in leaks and property damage. We offer a comprehensive polyurethane injection service to evaluate and perform necessary repairs using modern methods. As soon as you observe any visible leaks, it is wise to take action to protect your property against further water damage.

Polyurethane injection waterproofing can be applied in many areas of the building:

- Wet areas including toilets, showers and kitchens

- Concrete, tile or metal roofs

- Balconies and terraces

- Basements, foundations and retaining walls

- Water tanks