Contents

Polyurea Coating is internationally recognized as the ultimate coating system for roofs, basements, shafts, steels, tank linings and other applications. The durability and flexibility of the polyurea coating means it can be used in the world’s toughest conditions, including the hulls of ships and barges, aircraft carrier decks, North sea oil platforms for corrosion protection, pipe work protection and asbestos encapsulation.

The Polyurea Coating System has been developed over the past 20 years for use in the waterproofing industry for basement waterproofing, tanking, reservoir lining, roof and deck waterproof coatings, concrete and steel protection and tank lining.

Polyurea dries quickly, which allows for fast installation even at very low temperatures and is insensitive to water. It creates a high quality, waterproof elastic spray membrane that has many advantages over conventional waterproofing systems. It is very cost effective when compared to traditional solvent based products.

It is a hot spray applied through the Multiple Component Proportioning system. After the polyurea coating is sprayed, it can take foot traffic after 10 seconds and light vehicle traffic after a few hours. Polyruea coatings and primers are a high quality, seamless, ie jointless elastomer based on Polyurea with outstanding mechanical properties, chemical resistance and durability.

Polyurea Waterproofing Applications: Key Points

- Podium Deck.

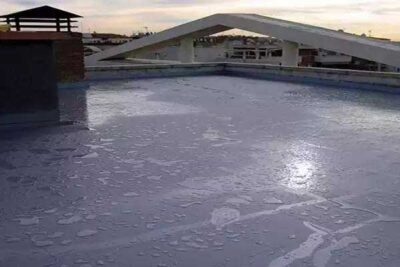

- Roof Waterproof membrane.

- External Type A Waterproofing.

- Parking deck waterproof membrane.

- Bridge membrane, decks.

- Water retention pool linings, Linings and Other Uses.

- Inner tank lining and protection.

- Waterproof floor coverings, including non-slip flooring for commercial and industrial facilities.

- Chemical resistant coating for tank and dock lining.

- Water Tank lining.

- Swimming Pool liner.

- Encapsulation of hazardous materials such as asbestos.

Advantages of Polyurea Coating System

- Fast curing, getting foot traffic in seconds and vehicular traffic in hours.

- Strong with high mechanical and wear resistance.

- High elasticity allows movement without leakage.

- 100% Waterproof membrane.

- High chemical resistance, suitable for oils, gasoline, acids and many other liquid chemicals.

- Provides fast curing, fast application and minimal downtime.

- Very good adhesion to both concrete and metals, even when damp.

- Vertical and horizontal application with spray application.

- It is hydrophobic and therefore unaffected by damp surfaces when creating unbonded waterproof liners.

- It can be sprayed at temperatures as low as -30°C with minimal impact on the tack time.

- It can be built to any thickness in one application, including vertical and overhead applications.

- The cured elastomer has high thermal stability with constant operating temperatures up to 130 °C and intermittent temperatures up to 160 °C.

Polyurea vs Polyurethane

Polyurea is closely related to polyurethane. Both are two-component systems made from Isocyanate-based materials. The second component in polyurethane is polyol resin, the other component is Polyurea, a polyether amine. In terms of performance, conventional polyurethane requires a temperature and humidity sensitive catalyst. Low temperatures can slow the reaction time, and moisture can interfere with the reaction, causing swell and other adverse effects.

Polyurea, on the other hand, does not require a catalyst. Reactivity for these coatings is fast, typically 3-10 seconds.

Polyurea can be sprayed at -20 °C, but they require a temperature of 5 degrees when primer is required.