For floor soundproofing, the issue of impact noise needs to be addressed. Impact noise is a sound from the structure created when two objects collide. This impact energy creates vibrations that resonate between the materials in the structure. Most people think of it as the “neighboring noise” of someone walking on the floor above or other activities. An acoustic floor sponge is used to block impact noise. It is placed under the finished flooring and the entire floor is covered. This will prevent structural sound from passing through the completed assembly.

Two main floor construction types; wooden beams and floorboards or concrete floors. Concrete floors have a high mass. Concrete floors will block out airborne sounds (speech, television). Impact sound (foot, moving furniture) will pass from the floor to the room below. Floor wood beams and floorboards can be a problem for both impact and airborne noise.

Wood and tile floors are very popular in homes today, as well as adding warmth and beauty to homes, they are easier to maintain and last longer. One downside to consider is that it tends to perform much worse acoustically. An untreated hardwood floor can produce erratic echoes and poor sound quality. If you’re considering tile or wood floors for your renovation, there are a variety of products and techniques that can reduce noise issues before they start.

Acoustic floor soundproofing is used between the floor and ceiling joists if you want to stop the airborne sounds from a wooden floor. Soundproofing between floor joists is the best way to reduce airborne sound between floors. To increase the soundproofing between floors, we recommend using 100 mm acoustic floor soundproofing and a density between 60 kg / m³-80 kg / m³.

Stopping airborne and impact sound will result in the highest level of floor soundproofing or both wood and concrete floors. Acoustic sponges are the most popular method of floor soundproofing. The combination of mass-loaded vinyl sheets (heavy sound barriers) and acoustic foams allows airborne and impact sounds to be reduced when applied to wood or concrete subfloors. If you don’t want to remove the floorboards, an alternative method would be to put the soundproofing barrier above the floor. High-density mass-loaded vinyl sheet to reduce airborne noises. These boards are quick and easy to install and increase airborne soundproofing.

To reduce floor noise in residential or commercial applications, the application of soundproof subfloors, underlays and boards when installing flooring significantly reduces sound transmission from one space to another. The ability to provide a quiet working or living environment with proper floor soundproofing is a huge advantage for everyone. As a leader in noise control products, our floor soundproofing products are available in many different styles and materials. Made from recycled rubber or synthetic fibers, these easy-to-install products are suitable for use under ceramic tile, hardwood, laminate and engineered wood floors or carpet.

By using floor soundproofing products specifically designed to reduce sound transmission, you can prevent the leading causes of tenant dissatisfaction. Quiet spaces are valuable in residential and commercial settings. To further reduce structure-borne sound, soundproofing barriers reduce impact noise and increase resistance to airborne sound.

Sound Insulation of Wooden Floors

Since a wooden floor can be both stylish and very elegant and modern, it is a great way to make a clear interior design statement. But more importantly, it’s affordable and easy to maintain. However, this type of flooring has one minor drawback when compared, for example, with carpets. Wooden floors often produce squeaky noises and amplify the sound. For this reason, floor soundproofing has become vital for homeowners who value comfort and silence.

Floor soundproofing flooring is the most popular and most effective way to reduce noise associated with wood floors. Any underlayment will lower the noise level, but if you want the best results, there is no better option than an acoustic underlayment. These types of pads have been developed with this particular application in mind. Good acoustic flooring can effectively reduce noise by 3/2. They differ in quality, effectiveness and cost, and in the case of an acoustic underlay you need to decide which features are important to you and what kind of product you can buy.

The wide selection of various acoustic floor coverings can be confusing, so choosing the right one can be difficult. Weight and thickness are the most important factors that determine the effectiveness of a litter in minimizing the noise level. In general, the thicker and heavier the underlayment, the better soundproofing it provides. What’s more, acoustic pads’ labels often have a sound rating to help you evaluate sound reduction effectiveness. The testing process for acoustic pads is very extensive, taking into account factors such as impact and air noise. Therefore, you can basically choose an underlayment that meets your noise reduction requirements.

To get the most out of your floor soundproofing project and achieve the most effective result, you may want to consider converting the floor to a floating floor. Acoustic insulation can also be used for soundproofing of a cavity wall with the same method.

Using Floating Floors for Soundproofing

A floating floor is a floor that is not glued or nailed to the subfloor. It fits freely into the subfloor, creating space for movement and vibration absorption. A floating floor sits on suction sponges and is not secured to the joists with nails or screws, which helps prevent vibrations from getting through the joists. There are several different ways to install a floating floor:

- A wooden basket-style weave – this is an ancient and complex technique of laying floors.

- Using sound-absorbing sponges or acoustic foam / rubber – this is the simplest method we have covered.

- Some floors use metal springs – these are the type of floors gymnasts use to do their floor routines. This method is rarely used outside of gyms.Beton Zeminlerin Ses Yalıtımı

Concrete floors carry a lot of mass, so they are exceptionally good on their own at soundproofing against airborne noise, but they transmit impact noise quite well. To soundproof a concrete floor, it is necessary to add an absorbent layer over the concrete to cushion any impact. A simple combination of underlayment and rug works very well. If necessary, an acoustic underlay designed to be extra dense to absorb more intense vibrations can be applied. Unless you have a serious problem with impact sound, standard underlayment and carpet combined with a concrete floor should be sufficient to effectively soundproof a concrete floor against impact sound.

Soundproofing a separating concrete floor and meeting Building Regulations demands is mainly about eliminating impact noise. Airborne noise is less of a problem, as the bulk of the concrete floor can absorb airborne noise transmission without the need to install soundproofing materials. A concrete floor awaiting sand cement or flowing screed installation requires the installation of a high performance soundproofing layer to eliminate impact noise.

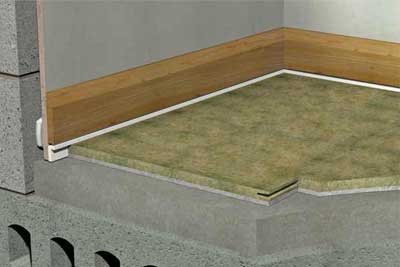

Acoustic solutions can be installed under the screed or above the screed. When mounted under the screed, an edge strip is also fitted to prevent acoustic burn-in. Acoustic combustion refers to noise escaping the acoustic floor treatment that could compromise Building Regulation tests. These solutions isolate the screed from the floor and significantly reduce impact noise. Alternative floor soundproofing solutions, including acoustic floorboards and battens installed directly on the concrete subfloor, save time as there is no need to wait for wet screed systems to dry before installing floor coverings.

Dry screed boards are a viable alternative to wet screed systems as the screeds contain many of the benefits of screed flooring without drying times. High-density boards, usually made of gypsum fiber, replicate the screed floor and can directly accept ceramic tiles. Sheets with a high performance, flexible layer provide excellent impact and weather performance. Other solutions include acoustic floorboards based on acoustic chipboard. The boards lack dry screed floor density and mass, but a high performance resilient layer provides the impact soundproofing performance required for concrete floors.

Acoustic floor slats are also a popular solution for concrete floors. The height of the slats creates a space where shuttles can be installed. An acoustic cradle system can also be adopted if concrete floors are uneven. The resilient layer at the base of both of these solutions can deal with the impact noise problem associated with concrete floors. All acoustic flooring solutions require the installation of an acoustic side strips to isolate the acoustic floor from the subfloor and prevent the risk of acoustic burnout. Edge strips are installed around the floor; failure to install them can compromise the performance of the floor and increase the risk of failure of Building Regulations.