Contents

- 1 What is Bitumen

- 2 6 Basic Applications of Bitumen Rubber Based Waterproofing Material

- 2.1 1. Corrosion protection (steel constructions, silos, walls, machinery)

- 2.2 2. Sealed surface (pantry, parking decks, flat roofs, storage pits, gutters, swimming pools, pond)

- 2.3 3. Protection or coverings (roofs, roads, residences, bridges, tunnels)

- 2.4 4. Airtight construction construction (real estate, parking lots, factories, offices)

- 2.5 5. Preventing rotting wood (playground equipment, furniture, fences, landscaping)

- 2.6 6. Home, garden and kitchen repairs (shower drains, window frames, pantry, drainage pipes, pond)

- 3 Bitumen Rubber Coating Application in 3 Steps

Bitumen rubber based waterproofing material is effective in waterproofing and protecting various substrates, especially metal, from the negative effects of corrosion. However, as with most protective coatings, proper surface preparation is key to their performance and effectiveness. Bitumen-polymer mixture / rubber coating has traditionally been offered on the market as a waterproof roofing coating. Recently, bitumen rubber coating has been further developed and can now be used for excellent sealing on a variety of surfaces.

What is Bitumen

Bitumen, also known as asphalt in North America, is a general term used to describe the classification of minerals mainly composed of carbon and hydrogen. Bitumen; It consists of several other elements, including nitrogen, sulfur, and oxygen. It also contains solid forms of iron and alumina. Physically, bitumen is a black, sticky and thick substance similar to the viscosity of molasses at room temperature. This liquid-to-semi-solid form of petroleum is typically found in natural underground deposits or may be a refined product classified as pitch. Like most petroleum hydrocarbons, bitumen is hydrophobic, meaning it repels water and does not mix easily with water. This property makes bitumen-based paints and coatings ideal for waterproofing a wide variety of objects and structures.

More than 70% of the bitumen consumption is for road construction, where it is used as a binder to form asphalt concrete. The remainder is mainly used for sealing, insulation and waterproofing purposes.

Bitumen-coated roofing felt, also known as waterproofing membranes, is used to protect flat and pitched roofs from water ingress and also as the base material for shingle roofs.

6 Basic Applications of Bitumen Rubber Based Waterproofing Material

Bitumen rubber based waterproofing material is a widely used product for special purposes. It is a very reliable sealant and coating agent that can be applied even to damp surfaces. This is also the perfect solution for large or industrial projects. Bitumen rubber based waterproofing material is a product that can be used on almost any substrate (steel, concrete, wood).

1. Corrosion protection (steel constructions, silos, walls, machinery)

There are many ways to protect steel from corrosion. But the biggest advantage of bitumen rubber is its complete adhesion to the surface. This protects the steel from corrosion even if mechanical damage occurs. Additionally, it is an anti-corrosion coating that camouflages and neutralizes rust.

2. Sealed surface (pantry, parking decks, flat roofs, storage pits, gutters, swimming pools, pond)

Bitumen rubber is ideal for filling leaks, holes or cracks where water can come in handy. It is covered even in relatively large cracks; The bitumen rubber based waterproofing material is particularly elastic and can stretch up to 800% of its original size. It can be applied to exterior structures such as seepage on a parking deck, but also in damp areas such as cellars. This makes bitumen rubber a strong example of a waterproof coating.

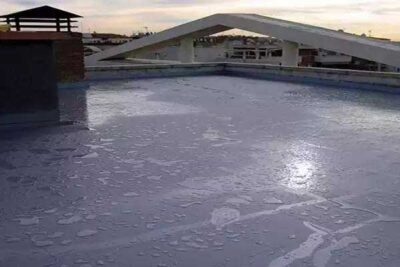

3. Protection or coverings (roofs, roads, residences, bridges, tunnels)

Its waterproof properties make it a good substrate or interlayer for water permeable materials such as concrete. It can also be used on flat roofs or as cover tunnels. You can learn more about coating options on roofs in our article on roofing. Therefore, damage and leaks to underlying structures are a thing of the past.

4. Airtight construction construction (real estate, parking lots, factories, offices)

Small gaps or small openings; For example, when building a house, they often cause an uncontrolled flow of air. Bitumen Rubber can prevent this due to its elasticity and is excellent as a substrate to make a house fully insulated or airtight. With this, he creates a sustainable solution; contributes to the energy efficiency of a building.

5. Preventing rotting wood (playground equipment, furniture, fences, landscaping)

The water-repellent properties of liquid rubber are also ideal for protecting wood from rotting. This thick, opaque layer provides extra durability for exterior wood structures.

6. Home, garden and kitchen repairs (shower drains, window frames, pantry, drainage pipes, pond)

Bitumen rubber, for small household chores thanks to its enormous flexibility; Perfect for filling holes and cracks in roof pipes, shower drains and outside. In addition, it can also be used to protect your pond and make repairs to basement waterproofing, for example.

Bitumen Rubber Coating Application in 3 Steps

One of the biggest advantages of bitumen rubber is its ease of application. There are only three basic steps for bitumen rubber based waterproofing application. Whether spray, brush, trowel or roller, the coating will provide solid bond strength to almost any surface. Concrete, stone, bitumen, EPDM, wood, PVC, metals, foam, tile, zinc etc.

1. Surface Preparation

Poor surface preparation can cause the coating system to fail; adhesion is affected, leading to the prevention of optimum performance.

A properly prepared surface is crucial to the optimal application and performance of a coating. In the case of bitumen rubber, the substrate must be clean, dry, free from oil, dust and other particles. It is recommended to wash the area vigorously. For the best waterproofing result, cracks on the surface should be repaired beforehand.

2. Application of the Coating

Always review and follow the manufacturer’s application instructions.

Liquid rubber should not be applied at temperatures below 5 °C or if rain is expected within 24 hours, so it should be acted upon according to the weather. It can be applied by brush, trowel, roller or spray and applied cold. The minimum layer thickness for a waterproof membrane is 2 mm. The coating is not applied in a single thick coat, it is done by layering.

3. Film Curing

The given curing times must be observed; Premature traffic on paved area can cause pavement failure and have a large financial impact.

After applying the bitumen rubber based waterproofing material, it must be cured. It will take 48 to 72 hours for the coating to fully cure and bond to the surface, although it can be touched up in just a few hours. After this point, normal traffic and use can continue.

The use of natural bitumen as a form of waterproofing can be traced back to 5000-4000 BC, and crop storage baskets covered with this material were discovered in Mehrgarh of the Indus Valley Civilization. Other discoveries reveal that bitumen was used in the same area, between 3000 and 2000 BC, to waterproof the Great Bath, Mohenjo-Daro. The Sumerians of the ancient Middle East also used bitumen for various construction purposes, including brick lining and filling ships and waterproofing. In modern society, increasing demands and harsh industrial environments have highlighted the importance of using bitumen to waterproof and protect various types of structures.